galvanization

Galvanization is a process superior to the standard anti-rust treatment of the metallurgical industry. The metal is first stripped of its impurities then dipped in molten zinc. This layer of zinc will protect it against corrosion.

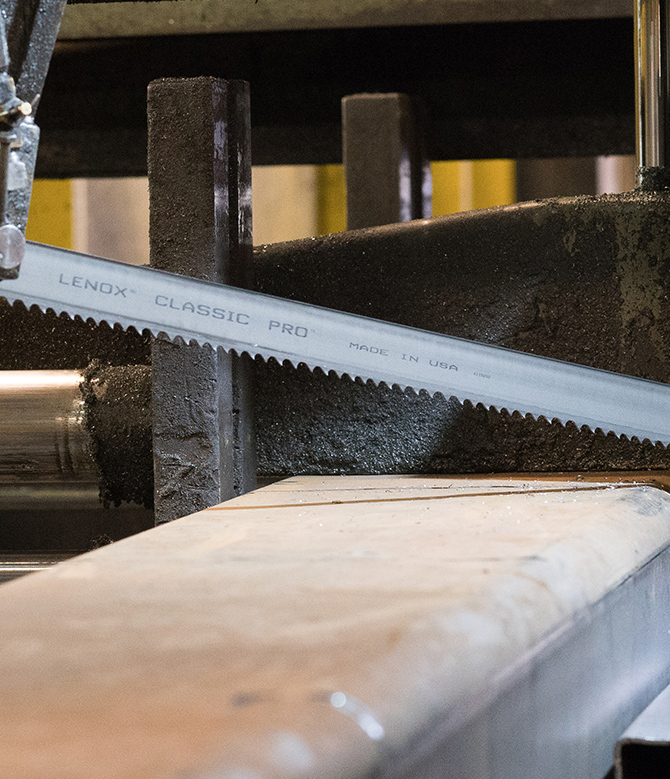

We can make cuts in exact dimensions as requested for any type of profile. Whether it’s for beams or rebar, angular or perpendicular cuts, our high-performance machinery we use offers great positional accuracy.

QUOTE

Using high technology, plasma is used to cut thin materials. Applying the effects of the electric arc, this method has the advantage of preventing warping. We can also cut pieces in a water basin to achieve an optimal result. As for the oxycutter, it’s automated and carries out the cutting by oxidation using a custom oxygen jet that can make cuts up to 6 inches thick.

QUOTE

Our guillotines let us cut your sheets of steel, aluminum, and stainless steel with precision according to the required dimensions. In addition, we’ll pack your order carefully, and we’ll place it all on a pallet for you, if you’d like.

QUOTE

Thanks to our guillotines and our machinery, we can cut your frames and bend them in the desired angle.

QUOTE

At your request, we’ll apply a coat of primer to your order. This special paint helps protect your steel from bad weather and preserve it for longer period of time.

QUOTE

Acier Ouellette can perform drilling jobs with precision, regardless of the diameter, depending on the thickness and size of your pieces.

QUOTE

Galvanization is a process superior to the standard anti-rust treatment of the metallurgical industry. The metal is first stripped of its impurities then dipped in molten zinc. This layer of zinc will protect it against corrosion.

We do business with a team of professionals capable of working with cutting-edge equipment to bend sheets of metal or rebar according to your requirements.

We’re able to offer you pipe bending service. This involves modifying your metal bar by performing various bending operations on it according to a specific angle and radius.

Our metal polishing service involves making the surface of your materials smooth and shiny to make your finished products more attractive.

Many of our partners have mastered the methods of welding and are qualified to meet the demands of our customers. They have all the necessary equipment to properly assemble your pieces.

The anodization process is a treatment that helps protect your aluminum by adding a thin insulating layer to it, giving it better resistance to heat, wear, and corrosion.

Thanks to the high skill level of our partners and their diverse equipment, they’re able to work your pieces and give them a specific shape according to your needs in order to realize all your projects.

At your request, we’ll apply a coat of industrial grade primer to your materials. This special paint helps protect the material from bad weather and preserve them longer.